Ivalvu yokukhishwa komoya UL/FM Ivunyelwe

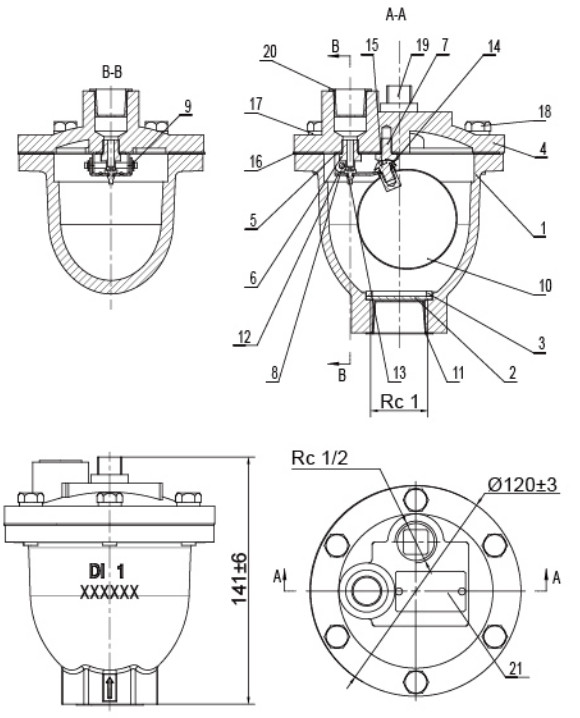

| I-S/N | Incazelo Yezingxenye | Izinto zokwakha |  |

| 1 | Umzimba we-valve | I-ASTM A536 65 45-12 | |

| 2 | Hlunga isikrini | I-SS316 | |

| 3 | Indandatho ye-Gasket | Insimbi ye-carbon | |

| 4 | Ibhonethi | I-ASTM A536 65 45-12 | |

| 5 | Ijoka | I-SS316 | |

| 6 | Isihlalo se-valve | I-SS316 | |

| 7 | Ibholidi | I-SS316 | |

| 8 | I-valve shaft | I-SS316 | |

| 9 | Thayipha indandatho yesilondolozi | I-SS316 | |

| 10 | Ibhola | I-SS316 | |

| 11 | Ikhava enkulu yokuvikela | Ipulasitiki | |

| 12 | L njalo | I-SS316 | |

| 13 | I-Poppet | I-EPDM | |

| 14 | Iwasha lasentwasahlobo | I-SS316 | |

| 15 | Ibhawodi lekhanda lesokhethi le-Hex | I-SS304 | |

| 16 | I-gasket engena-asbestos | I-CN-705 | |

| 17 | Iwasha lasentwasahlobo | Insimbi ye-carbon | |

| 18 | Ibholidi | Insimbi ye-carbon | |

| 19 | Ipulaki | I-ASTM A536 65- 45-12 | |

| 20 | Ikhava encane yokuvikela | Ipulasitiki |

Ukuxhunywa kwe-inlet kuyokwenziwa kusetshenziswa imicu yangaphandle yentambo yepayipi ecishiwe 1-11 1/2NPT ehambisana ne-ASME B 1.20.1-2013 evamile, futhi ukuxhunywa kokuphuma kuyokwenziwa kusetshenziswa imicu yangaphandle yomcu wepayipi ocijile ongu-1/2. -14NPT ihambisana ne-ASME B 1.20.1-2013 ejwayelekile.

Ukuxhunywa kwe-inlet kuyokwenziwa kusetshenziswa imicu yangaphandle yepayipi elicijile R21 elihambisana ne-ISO 7-1-1994 ejwayelekile, futhi ukuxhunywa kwe-outlet kuyokwenziwa kusetshenziswa imicu yangaphandle yomcu wepayipi ocijile R2 1/2 ohambisana ne-ISO ejwayelekile. 7-1-1994.

Ivalvu yokukhipha umoya ingaqinisekisa ukucinana okuhle kakhulu kokuvuza namandla amahle okukhipha umoya ngaphansi kwengcindezi elinganiselwe yokusebenza.Asetshenziswa ezinhlelweni zokufafaza amapayipi amanzi, noma ngamaphampu ekesi elihlukanisayo avundlile.

1.Ikhono lokwenza ngokwezifiso

I-2.Our own foundry(Precision casting/Sand castings) ukuqinisekisa ukulethwa okusheshayo kanye nekhwalithi

I-3.MTC kanye nombiko Wokuhlola uzonikezwa ukuthunyelwa ngakunye

4.Isipiliyoni sokusebenza esicebile sama-oda wephrojekthi