Ipayipi lensimbi elingenamthungo/ipayipi le-SMLS

| Izinhlobo | Isicelo |

| Izinjongo zesakhiwo | Isakhiwo esijwayelekile kanye nemishini |

| Amasevisi oketshezi | Uphethiloli, igesi nolunye uketshezi oludlulisayo |

| Ishubhu le-boiler enengcindezi ephansi naphakathi | Ukukhiqizwa kwe-steam ne-boiler |

| Isevisi yensika ye-Hydraulic | Ukusekelwa kwe-hydraulic |

| Isikhwama se-semi-shaft esizenzakalelayo | Isikhwama se-semi-shaft esizenzakalelayo |

| Ipayipi lomugqa | Ukuthutha uwoyela negesi |

| I-tubing kanye ne-casing | Ukuthutha uwoyela negesi |

| Gcoba amapayipi | Ukubhola kahle |

| Ipayipi lokumba le-geological | Ukumba Geological |

| Amashubhu omlilo, amashubhu okushintshanisa ukushisa | Amashubhu omlilo, izishintshi zokushisa |

| Okujwayelekile | Amabanga | Ikilasi |

| I-API | I-API 5L | Ipayipi lomugqa wezinhlelo zokuthutha zamapayipi |

| I-API 5CT | Amashubhu kanye ne-casing yemithombo | |

| I-API 5DP | Ipayipi lokubhoboza ukuze kubhojwe umthombo | |

| I-ASTM | I-ASTM A53 | Isetshenziswa njengensimbi yesakhiwo noma amapayipi anengcindezi ephansi |

| I-ASTM A106 | ipayipi le-carbon steel engenamthungo yesevisi yezinga lokushisa eliphezulu | |

| I-ASTM A335 | ngepayipi lensimbi elingenamthungo le-ferritic alloy-steel yesevisi yezinga lokushisa eliphezulu | |

| I-ASTM A213 | kubhayela wensimbi engenamthungo ne-austenitic alloy-steel, i-superheater, namashubhu okushintshanisa ukushisa | |

| I-ASTM A179 | Okokushintshanisa ukushisa kwensimbi ekhabhoni ephansi enekhabhoni ephansi kanye namashubhu e-condenser angenamthungo | |

| I-ASTM A192 | amashubhu ebhayela ensimbi yensimbi engenamthungo yesevisi enengcindezi ephezulu | |

| I-ASTM A210 | kubhayela wensimbi ye-carbon medium engenamthungo kanye namashubhu okushisa aphezulu | |

| I-ASTM A333 | ngepayipi lensimbi elingenamthungo lesevisi yezinga lokushisa eliphansi nezinye izinhlelo zokusebenza ezinokuqina kwenotshi okudingekayo | |

| I-ASTM A519 | ye-carbon engenamthungo kanye ne-alloy steel mechanical tubing | |

| I-ASTM A252 | ngezinqwaba zamapayipi ensimbi angenamthungo futhi ashiselwe | |

| I-DIN | Idatha ye-DIN 17175 | imigqa yamapayipi ensimbi engenamthungo ekwazi ukumelana nokushisa |

| I-DIN 1629 | amashubhu ayindilinga angenamthungo wezinsimbi ezingezona ama-alloys anezidingo zekhwalithi ezikhethekile | |

| I-DIN 2391 | amashubhu ensimbi angenamthungo adonsekayo noma abandayo asongwe ngokunemba | |

| I-JIS | I-JIS G3454 | ipayipi le-carbon steel engenamthungo yesevisi yengcindezi |

| I-JIS G3456 | ipayipi le-carbon steel engenamthungo yenkonzo yokushisa ephezulu | |

| I-JIS G3461 | ipayipi lensimbi elingenamthungo le-boiler kanye nesishintshi sokushisa | |

| EN | I-EN 10210 | kwezingxenye ezingenalutho zesakhiwo ezingenamthungo ezishisayo eziqediwe zezinsimbi ezingezona ingxubevange |

| I-EN 10216 | amashubhu ensimbi angenamthungo ngezinhloso zokucindezela | |

| BS | BS 3059 | amashubhu e-carbonalloy kanye ne-austenitic steel stainless steel anezindawo zokushisa ezicacisiwe eziphakeme |

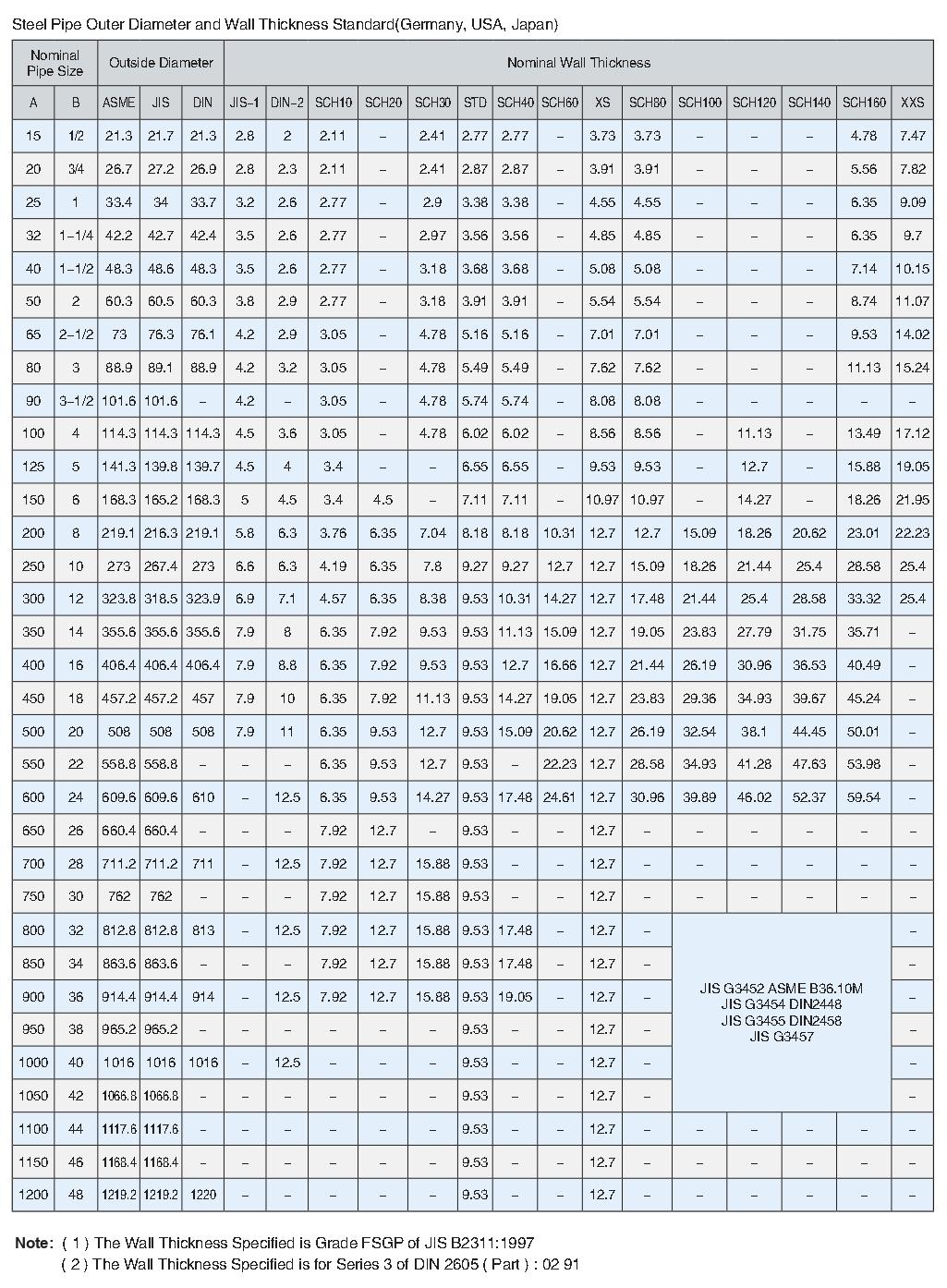

| Izinhlobo zamapayipi | Amasayizi wepayipi(mm) | Ukubekezelelana |

| Okushisayo kugoqiwe | OD <50 | ±0.50mm |

| OD≥50 | ±1% | |

| WT <4 | ±12.5% | |

| I-WT 4-20 | + 15%, -12.5% | |

| WT>20 | ±12.5% | |

| Kuyabanda | OD 6; 10 | ±0.20mm |

| OD 10-30 | ±0.40mm | |

| OD 30 - 50 | ±0.45 | |

| OD>50 | ±1% | |

| I-WT≤1 | ±0.15mm | |

| WT 1; 3 | + 15%, -10% | |

| WT >3 | + 12.5%, -10% |