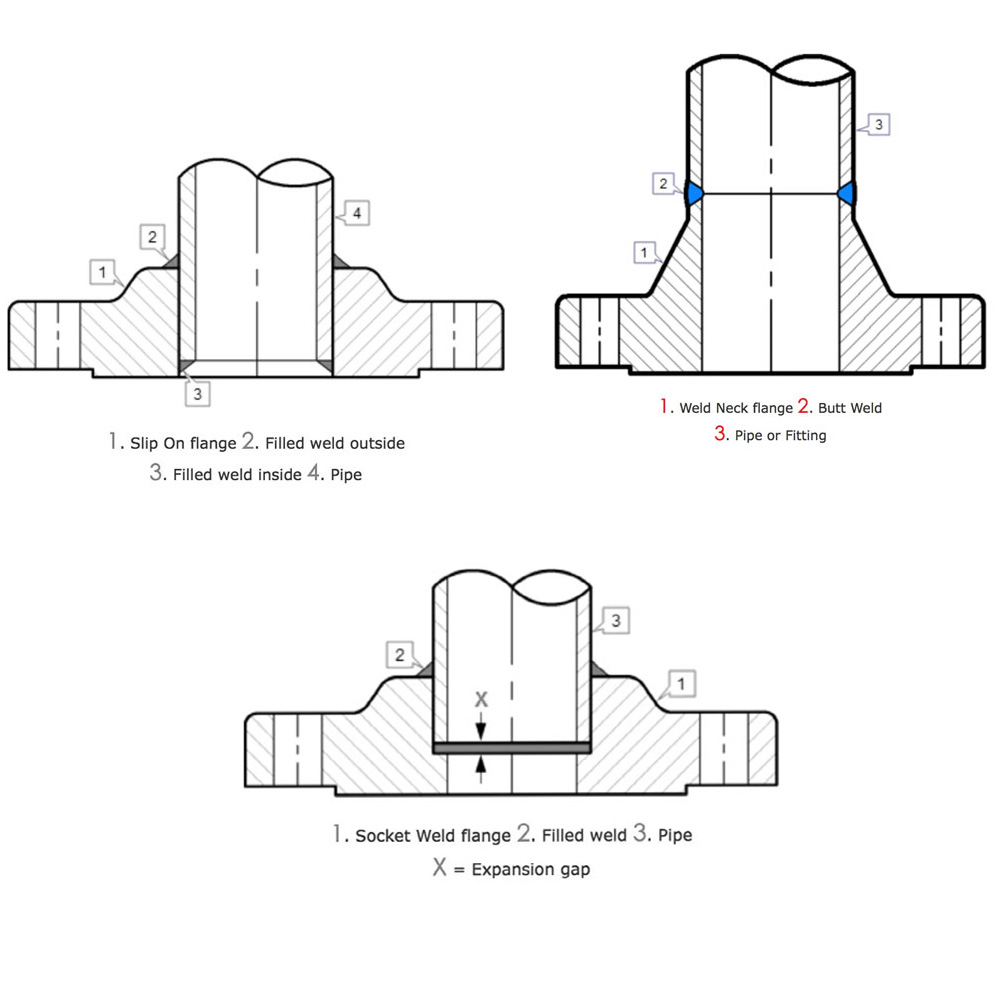

1.I-Flat welding, i-butt welding kanye ne-socket welding flange

I-Pipe flange welding inesimo sokushisela isicaba, i-butt welding kanye ne-socket welding flange

I-Socket welding ngokuvamile ifaka ipayipi phakathii-flangeokokushisela.Ukushisela izinqe kuwukushisela ipayipi nendawo yesinqe ngayoi-butt welding flange,Ukutholwa kwe-ray akukwazi ukwenziwa kwi-socket weld, kodwa ukushisela izinqe kungenziwa.Ngakho-ke, kunconywa ukusebenzisa i-butt welding flange ngezidingo zokutholwa kwe-welding ephezulu.

2. Umehluko eziningana kanye nezicelo

Ngokuvamile, izidingo zokushisela izinqe ziphakeme kunalezo zokushisela isokhethi, futhi ikhwalithi ngemva kokushisela nayo inhle, kodwa izindlela zokubona ziqinile.Ukushisela ukuze kutholwe amaphutha e-ray, i-socket welding yenza impushana kazibuthe noma ukuhlola ukungena kungaba (njenge-carbon steel do magnetic powder, insimbi engagqwali yenza ukungena).Uma uketshezi olusepayipini lungadingi ukushisela okuphezulu, kunconywa ukusebenzisa i-socket welding ukuze kutholakale kalula.

Iningi lezindlela zokuxhuma ze-socket welding zisetshenziswa kuma-valve amancane ububanzi namapayipi, ukufakwa kwamapayipi kanye nokushisela amapayipi.Amapayipi anobubanzi obuncane ngokuvamile mancane ngokuqina odongeni, kulula ukungaqondani kahle futhi avulwe, futhi kunzima ukuwashisela, ngakho afaneleka kakhulu ukushisela isokhethi.Ngaphezu kwalokho, i-socket welding ye-socket inomphumela wokuqinisa, ngakho-ke ibuye isetshenziswe ngaphansi kwengcindezi ephezulu.Kodwa-ke, i-socket welding nayo inemibi.Enye ukuthi isimo sokucindezeleka ngemva kokushisela asisihle, futhi kulula ukubangela ukungena okungaphelele kwe-welding.Kukhona izikhala ohlelweni lwamapayipi.Ngakho-ke, i-socket welding ayifanele isistimu yepayipi esetshenziselwa ukugqwala kwe-crevice medium kanye nesistimu yepayipi enezidingo zokuhlanzeka okuphezulu.Ngaphezu kwalokho, amapayipi anomfutho ophakeme kakhulu, noma ukushuba kodonga lwamapayipi anobubanzi obuncane nawo makhulu, angaxhunywa ngezinqe ngokusemandleni ukugwema ukushiselwa kwesokhethi.

Ngamafuphi, i-socket welding yakha i-fillet weld, kuyilapho i-butt ye-welding yenza i-butt weld.Kusukela ekuhlaziyeni amandla kanye nesimo sokucindezeleka se-weld, i-butt joint ingcono kune-socket joint, ngakho-ke i-butt joint kufanele isetshenziswe esimweni sezinga eliphezulu lokucindezela kanye nesimo esibi sesevisi.

3. Ukukhetha kwe-Flange

1.Ngokwempahla yepayipi ukukhetha impahla efanelekile ye-flange, njengepayipi lensimbi engagqwali ngokuqinisekile akuvunyelwe ukukhetha.i-carbon steel flange ;

2.Ngokwe-diameter yegama ( DN ) yepayipi kanye nomfutho wegama ( PN ) walo lonke uhlelo lwamapayipi, ilungeloi-flangeikhethiwe.Okwamanje, internationalipayipi flangengokuyisisekelo yamukela uhlelo olujwayelekile lwaseMelika kanye nohlelo olujwayelekile lwaseYurophu;

3. Ngokwezimo ezithile zokusebenza, ukwakheka kwe-flange kanye nefomu kukhethiwe: njenge-welding flat enentamo, i-loop flange, njll. .

Ezingxenyeni ezingezona ezijwayelekile, kuyadingeka ukuklama nokwenza ngokuya ngenqubo yokuklama imininingwane ye-flange.

Isikhathi sokuthumela: Feb-20-2023