Amafutha okudlulisa ukushisaluhlobo lwamafutha akhethekile anokuqina okuhle kokushisa okusetshenziselwa ukudlulisa ukushisa okungaqondile.Uwoyela we-Heat conduction awukwazi kuphela ukuhlangabezana nezidingo zenqubo yokushisa nokupholisa yamazinga okushisa ahlukene ebangeni elibanzi lamazinga okushisa, kodwa futhi uqaphela izidingo zenqubo yokushisa okuphakeme kanye nokupholisa okuphansi kwezinga lokushisa ngamafutha afanayo okushisa okushisa ohlelweni olufanayo, olungase. ukunciphisa ubunzima besistimu nokusebenza.Ngakho-ke, i-heat conduction oil heat system isetshenziswa kabanzi kuma-chemical fiber, impahla kanye nezinye izimboni.

Izici zesistimu kawoyela wokuqhuba ukushisa:

I-1.Ngaphansi kwesimo sengcindezi ecishe ibe yi-atmospheric, ingathola izinga lokushisa eliphezulu kakhulu lokusebenza - okungukuthi, linganciphisa kakhulu ingcindezi yokusebenza kanye nezidingo zokuphepha zokushisa okuphezulu kokushisa, ukuthuthukisa ukuthembeka kwesistimu nemishini;

2.Isistimu yokushisisa kawoyela ehambisa ukushisa ishiya isistimu yokuhlanza amanzi kanye nemishini, ethuthukisa ukusebenza kahle kokushisa kwesistimu futhi inciphise umthwalo wokugcinwa kokusebenza kwemishini namapayipi -- okungukuthi, ukutshalwa kwezimali kokuqala kanye nezindleko zokusebenza zesistimu yokushisisa kuncishiswe.

Izingozi ezingaba khona zokusebenza kwesistimu kawoyela oshisayo:

I-1.Ngenxa yokushisa kwendawo yesistimu yokushisa ngesikhathi sokusetshenziswa kwamafutha okushisa ukushisa, ukusabela kokuqhekeka okushisayo kujwayele ukwenzeka, okubangelwa ama-oligomers aguquguqukayo futhi aphansi.I-Polymerization phakathi kwama-oligomers ikhiqiza ama-polymers angancibiliki futhi angancibiliki, angavimbi nje kuphela ukugeleza kwemikhiqizo kawoyela futhi anciphise ukusebenza kahle kokwenziwa kokushisa okufanayo, kodwa futhi kubangela ukuthi kube nokwenzeka kokuguqulwa kokushisa okweqile kwendawo kanye nokuqhuma kwepayipi.

I-2. Amafutha okudlulisa ukushisa kanye nokugcwalisa umoya oncibilikisiwe kanye nesistimu yokuphatha ukushisa yindlela yokusabela kwe-oxidation yomoya osele ngaphansi kwesimo sokushisa, futhi ukwakheka kwe-asidi ephilayo kanye ne-colloid inamathela epayipini likawoyela, elingathinti kuphela impilo yesevisi yendawo yokudlulisa ukushisa kanye ivimba ipayipi, kodwa futhi ibangele kalula ukugqwala kwe-asidi yepayipi futhi yandise ubungozi bokuvuza kokusebenza kwesistimu.

Izingozi zokushisisa uwoyela wokudlulisa ukushisa zihlanganisa:umlilo we-thermal insulation layer, umlilo we-expansion tank exhaust kanye ne-thermal insulation layer, umlilo wendawo yokusebenza kawoyela wokudlulisa ukushisa, umlilo nokuqhuma kwethangi lokugcina uwoyela odlulisa ukushisa, umlilo nokuqhuma komshini wokushisa wokudlulisa uwoyela noma i-reactor (igedlela), ukuqhuma kwesithando somlilo, njll. Kungabonakala ukuthi izingozi eziningi ezivamile zokushisa uwoyela oshisayo zihlobene kakhulu noma ngaphansi nokuvuza.

Izidingo zevalvu zokucaciswa okujwayelekile kobuchwepheshe nedizayini ezinhlelweni zikawoyela oshisayo zifaka: an i-valve yokukhiphaendaweni ephakeme kakhulu kanye ne-valve yokushaywa phansi endaweni ephansi kakhulu.Umugqa wepayipi wesistimu yamafutha ashisayo kufanele uxhunywe nawoama-flangengaphandle kwezindawo zokusebenzelana zedivayisi, izixhumanisi zamathuluzi noma amavalvu.Zonke ezinye izixhumi ezibonakalayo zishiselwe.Ii-flangekufanele kusethwe indawo eyi-groove, futhi ingcindezi yokulinganisa akufanele ibe ngaphansi kuka-1.6MPa.Ukuze uwoyela wokushisa wokushisa onezinga lokushisa elingaphezu kwama-degrees angu-300, ingcindezi yegama le-i-flangeakufanele ibe ngaphansi kuka-2.5MPa.Ama-Flangeskufanele izinqe zishiselwe esikhundleni samaflange ashiselwe flat.I-flange gasket yesistimu kawoyela oshisayo ayivunyelwe ukusebenzisa ipuleti lerabha le-asbestos, i-metal winding pad noma i-graphite composite pad enwetshiwe kufanele isetshenziswe.Isistimu kawoyela oshisayo kufanele ihlinzekwe nge-valve yokuphepha, futhi i-valve yokuphepha kufanele ibe i-bellows sealed safety valve.

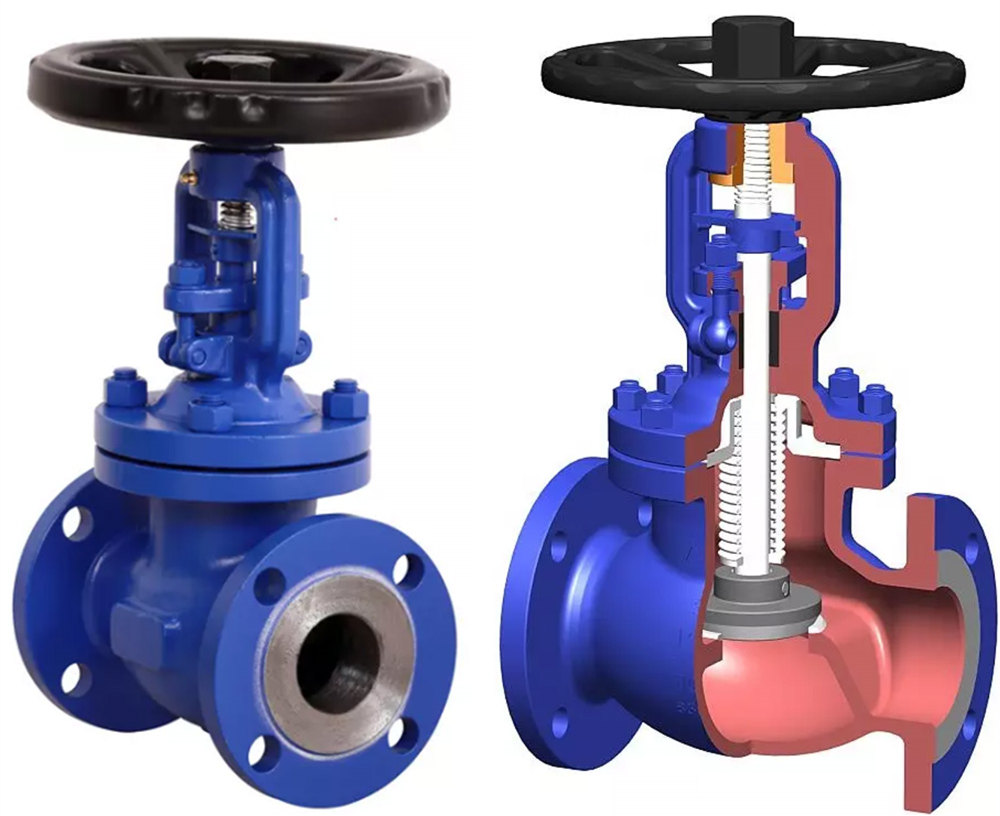

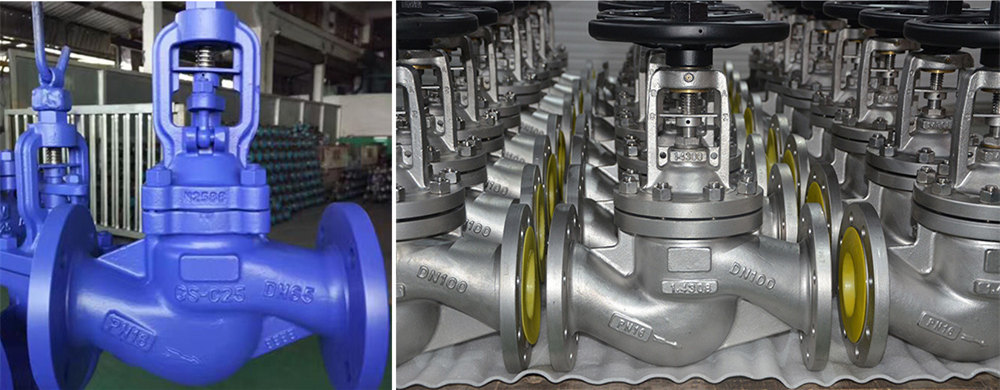

I-valve yesistimu kawoyela oshisayo akufanele ibe yinsimbi noma insimbi engeyona insimbi.Uma kucatshangelwa umfutho wayo ophansi, izinga lokushisa eliphezulu kanye nokungena kwamanzi kunamandla ikakhulukazi, ngokwezincazelo ezijwayelekile zokuklama kobuchwepheshe, i-valve kawoyela eshisayo enqamule kufanele isebenzise i-valve yokusika i-bellows seal, i-valve elawulayo kufanele isebenzise i-bellows seal sleeve elawulayo, i-valve yokuphepha isebenzisa i-valve yokuphepha ye-bellows evulekile egcwele.

Ngenxa yezimpawu zokuzinza kwe-oxidation kawoyela ohambisa ukushisa, ukuvuza kwe-valve kawoyela oshisayo ngeke nje kubangele ukushiswa kwesendlalelo sokufakelwa noma ukushiswa nokuqhuma kwemishini, kodwa futhi kubangele ukusabela kwe-oxidation kawoyela wokuqhuba ukushisa nomoya oncibilikisiwe. ukushisa, okukhiqiza i-organic acid corrosion valves yangaphakathi.Ngakho-ke i-valve yamafutha ashisayo akufanele nje ingenzi ukuvuza kwangaphakathi, kodwa futhi ingenzi ukuvuza kwangaphandle.

Ukupakisha okujwayelekile kwe-globe valve ukupakishwa ngokubunjwa kwe-graphite processing, uma ukuhlanzeka kwegraphite kungenele, ukumelana nowoyela kuzoba kubi kakhulu, lapho amafutha okushisa okushisa epakisha i-graphite, ukungcola okuthile ku-graphite kulula ukuncibilika ngokuqhutshwa kokushisa. amafutha, okuholela ku-graphite powder, akakwazi ukwenza ukupakisha kwe-graphite ukufeza umphumela wokuvala, lokhu kuyimbangela eyinhloko yokupakisha i-valve ngokuvamile ukuvuza.I-bellows seal ivimbela ukuthintana okuqondile phakathi kwamafutha ashisayo ne-graphite, okuxazulula inkinga yokuvuza kwamafutha ashisayo esiqwini lapho ukupakishwa kwegraphite kuncibilika.

Ngenxa yokuthi ukuvuthwa kwamafutha okushisa okushisa kunamandla kakhulu (cishe izikhathi ezingu-50 kune-steam), uma uphawu lokugcwalisa lukhethiwe, kulula kakhulu ukuvuza, okuholela ekumoshweni kwamafutha ashisayo, imishini engcolile nomhlabathi, kanye nesakhiwo se-bellows. angabona ngokuphelele ukuvuza kwe-zero, futhi azikho izingxenye ezigqokiwe.

Ngenxa yengozi engaba khona yokuqina kwe-oxidation kawoyela ohambisa ukushisa, izingxenye zangaphakathi zevalvu zenziwe ngensimbi engagqwali, ekwazi ukumelana nezinga lokushisa elingu-425 ℃, ukumelana nokugqwala, futhi ukushintshwa kulula kakhulu.

Kusukela ekubukeni kwayo yonke impilo, impilo yesevisi yomuntu jikelelei-valve yokuvala i-bellowskungcono kunamanye ama-valve.Amafutha okudlulisa ukushisa ane-viscosity ephezulu kanye nokumelana nokugeleza okukhulu esimweni esibandayo.I-valve core isebenzisa uhlobo lokuvula ngokushesha, olungathuthukisa izinga lokugeleza futhi lunqobe ukumelana nokugeleza kahle lapho uqala.Ngakho-ke, ukuze kuqinisekiswe ukuzinza kokukhiqiza, kodwa futhi ukuze kuncishiswe izindleko zangempela zokusebenza, uhlelo lwamafutha okudlulisa ukushisa kufanele lukhethe umgogodla wokuvula okusheshayo we-valve.i-valve yokumisa uphawu, ayikwazi ukukhetha i-valve yokumisa uphawu lokupakisha noma i-valve evamile.

I-Bellows evala i-valve ye-globeekhiqizwe i-BESTOP ifaneleka kakhulu ukunqamula ukuthuthwa kwepayipi lohlelo lukawoyela oshisayo.

Isikhathi sokuthumela: Jan-29-2023