Leli phepha lichaza ii-valveukukhethwa kohlelo lwenethiwekhi yamapayipi okushisa kanye nezinzuzo, isimiso sokusebenza nokugcinwa kwe-i-valve yebhola, ehlinzeka ngenani elibalulekile lereferensi yokuhlela umthombo wokushisa, idizayini, ukukhethwa kwemishini, ukusebenza nokukhiqiza, ukugcinwa kwezinto zokusebenza, nokuguqulwa nokuthuthukiswa kwesistimu yokushisisa.

Eminyakeni yamuva nje, ngokuthuthuka komnotho kanye nokunaka kwabantu ekuvikelweni kwemvelo kwekhabhoni ephansi, ukubuswa kwamaphrojekthi wobungu kanye nokonga amandla kwenze amabhizinisi amaningi okushisisa aqhubekele phambili kancane kancane aqonde kumodi yokushisisa esezingeni, yesayensi nesekelwe kumandla. , okunciphisa kakhulu izindleko zokushisa futhi kuthuthukise izinga lezinsizakalo zokushisa.Njengamanje, ukusetshenziswa kwamandla eShayina kuye kwaba ukukhula okuphezulu, ukusetshenziswa kwamandla aphezulu, isimo sokungcola okuphezulu, ukongiwa kwamandla kubalulekile.Ukwakhiwa nokuthuthukiswa kokushisisa okuphakathi kwedolobha kuyindlela ephumelelayo yokonga amandla, ukunciphisa ukungcoliswa kwemvelo kanye nokuzuza intuthuko esimeme.

Njengamanje, iningi lamabhizinisi okushisa abheka izindleko zokutshalwa kwezimali, asasebenzisa izindlela zokukhiqiza ezibuyela emuva iminyaka eminingi, kanye nokuhlelwa komthombo wokushisa okungenangqondo, imingcele yokusebenza engenangqondo, izindlela zokuphatha emuva kanye nokushoda kwabasebenzi abaqeqeshiwe nabachwepheshe. , okuvimbela ukuthuthukiswa kwesayensi kwemboni yokushisa.Ohlelweni lokushisisa, ukukhethwa okufanele kwemishini yokulawula uketshezi kanye nomklamo wokuhlela umthombo wokushisa kube umsebenzi oyinhloko webhizinisi ngalinye lokushisisa.Ii-valveungomunye wemishini ejwayelekile kakhulu ohlelweni olushisayo.Izinga lei-valvenokuthi ngabei-valveikhethwa ngokufanele ngokwezimpawu ze-i-valveizodlala indima ewujuqu kukhwalithi yokushisisa.

Ii-valveingxenye yokulawula ohlelweni oludlulisa uketshezi oludlulisa uketshezi, olunomsebenzi wokusika, ukulawula, ukuqondisa, ukuvimbela i-countercurrent, i-stabilizing pressure, shunting, yokulawula ibhalansi yokugeleza okuphakathi nokunye.Kuhlelo lokushisa, ukushisa okubangelwa ikhwalithi yei-valveayikho ezingeni, futhi izikhalazo zomsebenzisi enkampanini yokushisisa nazo zivamile.Ngenxa yokuthi ama-valve abekwe emthonjeni, ukugijima, ukuwa, ukuvuza nokuvuza akulula ukutholakala.Ngokuvamile, ingatholakala kuphela lapho umsebenzisi ekhononda, ukutholakala kwe-Roving kanye nemishini yonakele.Uma kunenkinga, ayikwazi ukutholakala ngesikhathi.Akuyona inkinga encane, enomthelela ekuphepheni kokusebenza kwamapayipi, kodwa futhi ibangela ukuchithwa komthombo wokushisa.Ikhanda elibuhlungu kochwepheshe abashisayo.Kwamanye amabhizinisi okushisa, kube nokungaqondi kahle ekukhetheni ama-valve.Banaka kuphela intengo yemishini noma bebesebenzisa imodi yemishini yokufudumeza yangaphambilini.Ukuntula ukwazi okusha, ukuntula ulwazi lochwepheshe lwezimpawu ze-valve nokugcinwa.Ayicabangi izindleko eziphezulu zokulungisa ezibangelwa inkinga yekhwalithi ye-valve.

Ama-valve asetshenziswa kakhulu ohlelweni lwamapayipi ashisayouvemvane valve, i-valve yesango, i-valve yomhlaba, hlola i-valvenjalo njalo.Lawa ma-valve anezinzuzo zawo siqu, kodwa futhi aneziphambeko zawo, asetshenziswa kabanzi ohlelweni lwenethiwekhi yokushisa, nomklami ekukhethweni kohlobo, ngokuvamile ngokusetshenziswa okusebenzayo okuhlangene nezinzuzo kanye nokungalungi kwalawa ma-valve ngokuhlelwa kokuklama okunengqondo.Masiqonde izinzuzo nezinkinga zalawa ma-valve,uvemvane valveingenye ye-valve esetshenziswa kakhulu, indawo yokufaka incane, izindleko eziphansi, ingasetshenziswa futhi ukulungisa ukugeleza kwe-valve butterfly ephakathi, i-soft seal valve ngenxa yemikhawulo yezinto zenjoloba, ayikwazi ukusetshenziswa ezimweni zokushisa eziphakeme, muva nje. iminyaka,i-valve ye-butterfly yensimbi emithathu eccentricisicelo, ngcono kakhuluuvemvane valveebangeni lokushisa kwesicelo, Nokho, ipuleti uvemvane wageza medium isikhathi eside, okuholela deformation of the surface sealing, okuzokwenza umonakalo uphawu futhi kuthinte ukugeleza medium.Ngokuvamile isetshenziswa ezikhathini lapho izidingo zokuvala zingaqinile.Ngoba ukumelana uketshezi of thei-valve yesangokuncane, isiqondiso sokugeleza kwe-medium akukhawulelwe, lapho indawo yokuvala ivuliwe ngokugcwele, ukuguguleka kwe-medium kuncane kunokwe-i-valve yomhlaba, kodwa ubukhulu nokuphakama kokuvula kwe-i-valve yesangozinkulu, futhi indawo yokufaka inkulu uma kuqhathaniswa.Enkambweni yokuvula, ukungqubuzana okuhlobene kwendawo yokubeka uphawu kulula ukubangela into yokufaka, futhi ukugcinwa kubuye kube yinkinga enkulu, ethinta ukusetshenziswa kwamanani amakhulu ohlelweni lokushisa.Ii-valve yomhlabaibuye isetshenziswe ngokuvamile ohlelweni lwe-valve, ukuphakama kokuvula kuncane, ukushintshwa kuyashesha kakhulu, indawo yokubeka uphawu ngesikhathi sokuvula nokuvala ngokuvamile akukho ukushelela kwesihlobo, ngeke kubangele imihuzuko, ukugcinwa kubuye kube lula, kodwa ukonakala ukushintsha ukugeleza kwe-medium, ukwandisa ukumelana noketshezi, ubude bomumo bubuye bukhulu, ububanzi obujwayelekile be-valve yembulunga yonke abukho ngaphezu kwe-DN250 ukucindezela okuphezulu akukhulu kune-DN150.

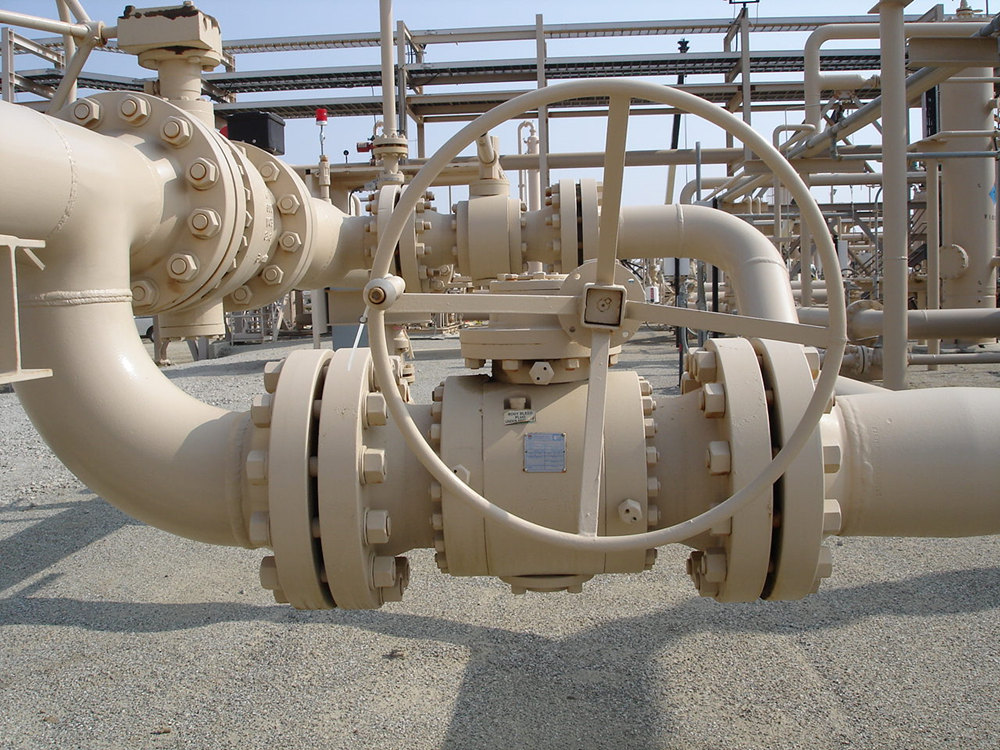

I-valve yebholawazalwa ngawo-1950, ngokuthuthuka ngokushesha kwesayensi nobuchwepheshe, ukuthuthukiswa okuqhubekayo kwenqubo yokukhiqiza kanye nesakhiwo somkhiqizo, sekusetshenziswe kakhulu ohlelweni olushisayo eminyakeni yamuva, ukusebenza kwayo okuphezulu kungaphezu kokufinyeleleka kwamanye ama-valve. , ayinakho ukumelana noketshezi, isisindo esilula, ukusebenza kokuvalwa kokuvuza kwe-zero, ukuvula nokuvala inkinobho ngokushesha, indawo yokuvala ayigudluzwa yi-medium, Impilo yesevisi ende nezinye izinzuzo, futhi ithola umusa wokukhethwa kwama-valve kumabhizinisi.Ikakhulukazi, i-valve yebhola ene-welded isetshenziswe kabanzi kunethiwekhi yamapayipi okushisa aphakathi eminyakeni emibili edlule.Izinzuzo zayo eziyingqayizivele zokuvuza kweqanda kwangaphakathi nangaphandle, ukungcwatshwa okuqondile, ukushiselwa kwamapayipi ngaphandle kwengcindezi, kanye neminyaka engama-20 yokungalungiseki, ngokwezinga elikhulu, kusindise izindleko zokufakwa kanye nezindleko zokunakekela ezihlobene namabhizinisi okufudumeza, futhi kuye kwaqashelwa abaphathi abaphezulu benkampani yokushisisa.Kodwa-ke, indlela yokwenza ukugcinwa nokulungiswa kwansuku zonke kwama-valve ekusebenzeni kwethu kuye kwaba umsebenzi ongenakunakwa ngamabhizinisi okushisa.Ngokuqonda isimiso sokusebenza kanye nezici zomkhiqizo we-valve, kanye nendlela yokusebenza nokuxazulula izinkinga, uhlelo lokusebenza olufanele lokukhiqiza lungenziwa ekukhiqizeni okujwayelekile kwenkampani ukuze kuqinisekiswe ukusebenza okuphephile kwemishini ye-valve.

Umgomo wokusebenza wokuvalwa kwe-valve yebhola ye-welding eshisayo:

I-welding esetshenziswa kakhulu ye-thermali-valve yebholakanye ne-valve yebhola ye-flange evamile ikakhulukazi yakhiwe umzimba we-valve, isihlalo, ibhola, isiqu kanye nedivayisi yokudlulisela.Umsebenzi oyinhloko ukuxhuma nokusika umgudu woketshezi osephayiphini.Ii-valve yebholaibona umsebenzi wokushintsha ngokushayela ibhola ukuze lijikeleze amadigri angu-90 ngokusebenzisa idivayisi yokudlulisela.Izinhlobo eziyinhloko zesakhiwo zihlukaniswe ngesakhiwo sebhola elintantayo kanye nesakhiwo sebhola esingashintshi.

1.Isakhiwo sebhola elintantayo:Ibhola lei-valve yebhola elintantayoingantanta emzimbeni we-valve, ngaphansi kwengcindezi ye-fluid medium, ibhola licindezelwe ngokuqinile engxenyeni yokuphuma yesihlalo se-valve yokuvala, esizokwakha uphawu olulodwa, uphawu lwesihlalo sangaphambili aluqinisekisiwe, lesi sakhiwoi-valve yebholaibonakala ngesakhiwo esilula, ukukhiqiza okulula, ukusebenza kokuvalwa kwe-unilateral kuhle, ikakhulukazi i-valve yesihlalo esigcwele ngokugcwele i-disc spring structure design design, ukuze uphawu lufinyelele ezingeni eliqinile, indawo yokubeka uphawu ukuze imelane nesilinganiso esikhulu sokuvalwa, ukuvulwa kanye i-torque yokuvala izokhula, Ivame ukusebenza kuma-valve anobubanzi obungaphansi kwe-DN300.

2.Isakhiwo sebhola esilungisiwe:Ibhola lesakhiwo esinqunyiwe line-shaft ejikelezayo engaphezulu nangaphansi, futhi ingxenye engezansi yebhola ifakwe nge-bearing, elungiswa yi-stem valve engezansi, futhi ingxenye engaphezulu ixhunywe ku-stem ye-valve ephezulu.Ibhola lingakwazi ukuzungeza kuphela i-axis eqondile yesiteshi se-valve, futhi alikwazi ukuya ohlangothini olulodwa njengei-valve yebhola elintantayo.Ngakho-ke, lapho i-i-valve yebhola engashintshiisebenza, ukucindezela koketshezi oluphambi kwe-valve kungadluliselwa kuphela ku-valve stem kanye nokuzala, futhi ngeke kukhiqize ukucindezela esihlalweni se-valve.Ngakho-ke, isihlalo se-valve ngeke sikhubazwe ukushintsha kwengcindezi epayipini, ukusebenza kokuvala kuhle, nempilo yesevisi yinde.Isihlalo sevalvu yevalvu yebhola engashintshi siyantanta, futhi isihlalo sevalvu sizosebenzisa ukucindezela kwentwasahlobo engemuva kanye nokucindezela kwepayipi ukuhlanganisa ibhola ukuze kwakhe uphawu oluthembekile.

Ukugcinwa kwe-valve yebhola eshisayo nobuchwepheshe bokuphatha:

Ukusetshenziswa okulungile kokufakwa nokugcinwa kwe-i-valve yebholakubaluleke kakhulu, futhi kungukuqukethwe inkampani yokushisisa okufanele ibhekisele kukho ekwakhiweni kwenqubo yokusebenza.Ukuphathwa kwesayensi nokugcinwa kwe-i-valve yebholangesikhathi sokwakha akukwazi nje ukuqinisekisa ukuphepha, kodwa futhi kunciphise izindleko zesikhathi sokuphatha ukwakhiwa nokusebenza.Ikakhulukazi naka izici ezilandelayo:

1. Ukuze usebenzise indlela efanele yokulayisha nokukhipha i-valve, ukugwema ukulimala komshini ku-valve, ukuphakamisa i-valve, ibhande eliphakamisayo alikwazi ukuboshwa ku-valve stem noma ukuphakamisa i-actuator, njengokusebenza okungekho emthethweni, kuzodala i-valve. ukugoba isiqu, ukwehluleka ukuvala isiqu se-valve kanye nokulimala kwebhokisi le-turbine.

2.Ngaphambi kokuthi i-valve ihambe embonini, kuyadingeka ukuvala ipuleti eliyimpumputhe noma ukumboza kuzo zombili iziphetho ze-valve ukuze ugweme amanzi, isihlabathi, nokunye ukungcola esizeni kungena ekamelweni le-valve ngesikhathi sokuthutha, okuzodala umonakalo nokugqwala. kuphawu.

3.Endaweni yokwakha, i-valve kufanele ibekwe ngobunono, ayikwazi ukubekwa ngokungahleliwe, izodala i-valve blowdown valve noma ukuphuka kwevalve yamafutha kanye nokulimala.

4.Ukushisela okugcwelei-valve yebholaNgaphambi kokwakhiwa kwe-Welding, kufanele uqinisekise i-valve endaweni yokushisela evulekile ngokugcwele, Gwema ukulimala kwebhola okubangelwa i-welding spatter, bhala indawo yokubeka uphawu, izinga lokushisa le-welding yesihlalo se-valve lilawulwa ngama-degree angu-140.

5.Ngemva kokuhlolwa kwe-hydrostatic, amanzi egumbini le-valve kufanele akhishwe ahlanzekile ukuze avimbele ukugqwala kanye ne-icing.

Iziphakamiso zokuphatha nokugcinwa kokugcinwa kwansuku zonke kusebenza:

1.Okwepayipiama-valve ebholaye-API6D, ngezikhathi ezithile hlola ukusebenza kokuvala kwama-valve, futhi uhlole nge-valve ye-blowdown.Uma kukhona ukuvuza kwangaphakathi, kusetshenzwa ngokwenqubo

2.Ngokwemvamisa yomsebenzi we-valve, inani elithile lamafutha lifakwa esihlalweni se-valve.Ngokuvamile, inani elifanele lamafutha liyajovwa ngemva komsebenzi wevalvu, futhi inani lomjovo ngamunye liyi-1/8 yohlelo lokuvala.Inhloso yokwenza lokhu ukugwema ukungcola okusepayipini lokungena endaweni engemuva yesihlalo se-valve ngezinga elikhulu kakhulu, okuthinta ukunyakaza kwesihlalo se-valve, okuholela ekuhlulekeni kokuvala, kuyilapho kuqinisekisa ukuthi indawo yokuvala ihlezi isendaweni. isimo sokugcoba nokwelula impilo yesevisi.

3. Ngama-valve anemisebenzi embalwa, ukuvula nokuvala kufanele kwenziwe kanye ngonyaka, futhi inani elithile lamafutha kanye noketshezi lokuhlanza kufanele lijovwe, elingagwema ibhola nesihlalo se-valve glue futhi kungagwema ukugaya okomile lapho ibhola liyasebenza futhi linciphisa itorque yokusebenza kwe-valve.

4. I-valve yebholakufanele igcinwe ngaphambi kobusika, igxile ekukhipheni amanzi ngaphakathi kwegumbi le-valve namanzi e-actuator ukuze kugwenywe ukubanda ebusika futhi kuphazamise ukusetshenziswa komsebenzi.

5.Faka igrisi engagugi ku-actuator yekhanda le-valve worm njalo ngonyaka, hlola njalo uphawu lwe-valve stem, khipha ukugqwala, futhi wenze isivikelo sangaphandle.

Ukuze kuthuthukiswe ukuthembeka kwe-valve nokwandisa impilo yesevisi ye-valve, kubaluleke kakhulu ukwenza umsebenzi omuhle ekunakekeleni nasekuqondiseni kusenesikhathi.Kuyadingeka ukuqinisa ukugadwa kwesondlo ngaphambi kokuba impahla ye-valve ishiye ifekthri kanye nokugadwa kwezokuthutha, futhi kuqiniswe ukunakekelwa ngaphambi kwendawo yokufaka imishini kanye nokugadwa ekufakweni kwayo.Ngaphambi kokufakwa, kuyadingeka ukwenza ukuhlolwa kwe-hydraulic, ukuthola izinkinga kusenesikhathi futhi ubhekane nezinkinga ngesikhathi.Qinisa ukuqeqeshwa kochwepheshe, uthuthukise amakhono kanye nekhwalithi yabasebenzi abalungisayo abaqeqeshiwe, futhi uzuze ukugcinwa kwesayensi, okujwayelekile nokuphephile.Shintsha umqondo, lawula ukugcinwa kokuvikela, yenza izinhlelo zokulungisa ngezikhathi ezithile futhi uzisebenzise ngokuqinile.Yenza umsebenzi omuhle ekusebenzeni okuphephile kwesistimu yokushisa ukuze uqinisekise ikhwalithi yokushisa.

Isikhathi sokuthumela: Feb-14-2023